随着科技的发展,人们生活水平的提高,对一些工具的要求也有所提升。在模具上来讲,在传统的电子、机械制造业上,更多的行业对模具有了更高的要求。

With the development of science and technology and the improvement of people's living standards, the requirements for some tools have also been improved. In terms of plastic mold, in the traditional electronic and mechanical manufacturing industry, more industries have higher requirements for mold.

任何模具都不是一成不变的,很多时候由于各种各样的原因,例如不合理的了利用,不正当的保养,都会造成模具的损坏,这时我们就要分析造成这一现象的原因,并能做到及时的整修了,那么该如何做呢?

Any mold is not immutable, many times due to a variety of reasons, such as unreasonable use, improper maintenance, will cause mold damage, then we have to analyze the cause of this phenomenon, and can do timely repair, so how to do?

护坡模具的保养:运用模具后有必要磨刃口,研磨后刃口面有必要进行退磁,不能带有磁性,不然易发作堵料。在运用过程中冲头易呈现折断、曲折和啃坏的表象,冲套一般都是啃坏的。

Maintenance of slope protection mold: it is necessary to grind the edge after long-term use of plastic mold, and demagnetize the edge surface after grinding, which can not be magnetic, otherwise it is easy to block materials. In the process of application, the punch is easy to appear broken, tortuous and gnawing, and the punching sleeve is generally gnawed.

冲头和冲套的损坏一般都用一样标准的零件进行替换。养护模具时查看各部位的配件联系及有无损坏,对损坏的有些进行修正,气动顶料查看有无漏气表象,并对详细的状况采纳方法。

Punch and punch sleeve damage are generally replaced with the same standard parts. During the maintenance of the mold, check the connection and damage of the parts, correct the damaged parts, check the air leakage appearance of pneumatic jacking, and adopt the method for the detailed condition.

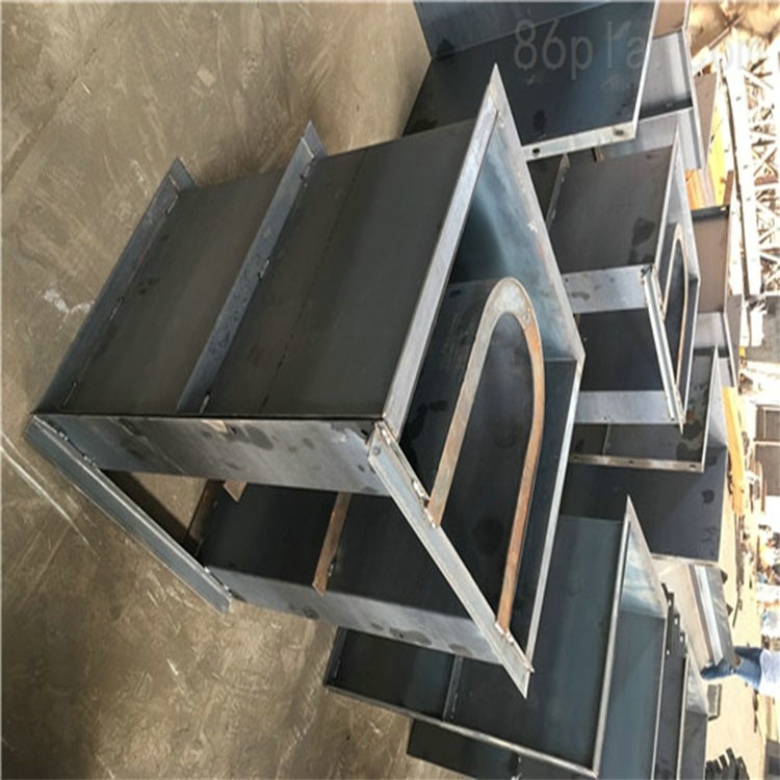

我厂积十几年模具制造的经验,十余年来,研制开发各类护坡模具,研制生产的模具,通过不断优化设计,集高精度、高稳定性和实用性于一体,结构合理,操作简便,整体性能优良,保证了该模具的高品质,受到广大用户的青睐。

Our factory accumulated more than ten years of mold manufacturing experience, more than ten years, professional committed to the development of various types of slope protection mold, research and production of mold, through continuous optimization design, set high precision, high stability and practicality in one, reasonable structure, easy operation, excellent overall performance, to ensure the high quality of the mold, favored by the majority of users.