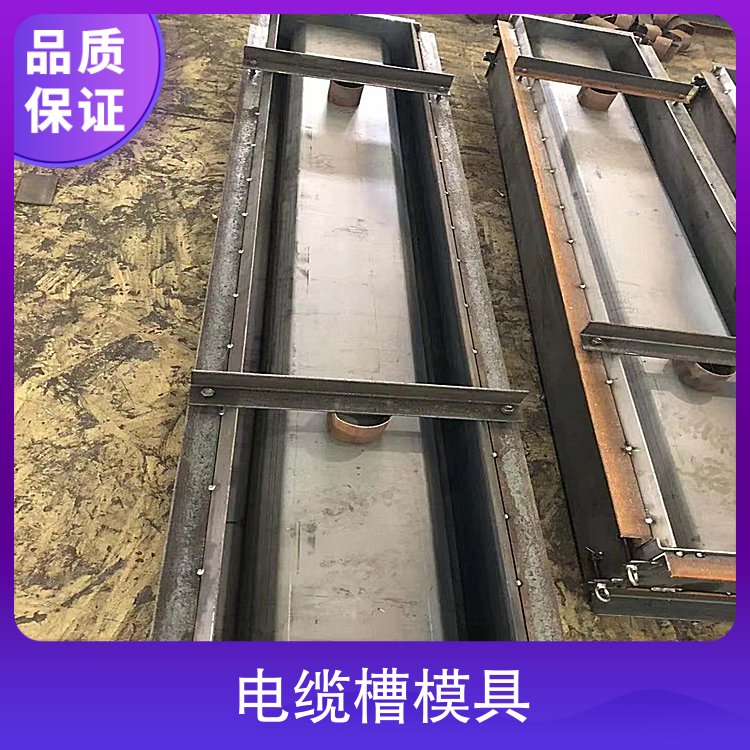

我们见到的各种各样的电缆槽模具都是经过时间的沉淀来总结出来的,也有根据当下的发展形势来研究的一些新型的样式,每一种样式的电缆槽模具都为环境的使用起着作用,在设计电缆槽模具时需要注意的事项比较多。

All kinds of slope protection molds we see are summed up through the precipitation of time. There are also some new styles researched according to the current development situation. Each style of slope protection mold plays a role in the use of the environment. There are many matters needing attention in the design of slope protection mold.

首先在设计电缆槽模具时要选择好模具的材料,因为模具的样式不是一蹴而就的,需要经过多次的试验,所以多准备几种模具的材料以保证适合模具的生产技术。

First of all, when designing the slope protection mold, the material of the mold should be selected. Because the mold style is not achieved overnight, it needs to be tested many times. Therefore, several kinds of mold materials should be prepared to ensure the production technology suitable for the mold.

其次根据生产厂家的产品密度以及生产原料的主要性能及配比,确定产品的压缩率,再次使用独特的非焊接式结构以保证在制作过程中模腔保证正常的工作状态,

Secondly, the compression ratio of the product is determined according to the product density of the manufacturer and the main properties and proportions of the raw materials. The unique non welded structure is used again to ensure the normal working state of the die cavity during the manufacturing process,

最后要保证模腔与各个零件之间的间障不能超过1毫米以保证产品外形以及质量的稳定,只有在模具设计时注意以上问题就能制作出产品。

Finally, it is necessary to ensure that the gap between the cavity and each part should not exceed 1 mm, so as to ensure the stability of product appearance and quality. Only by paying attention to the above problems in mold design, can we make better products.